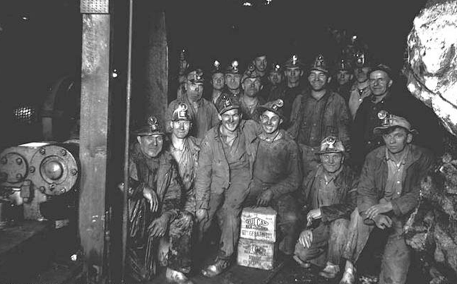

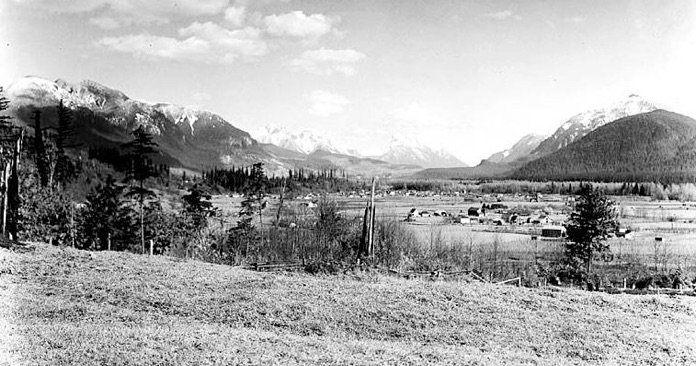

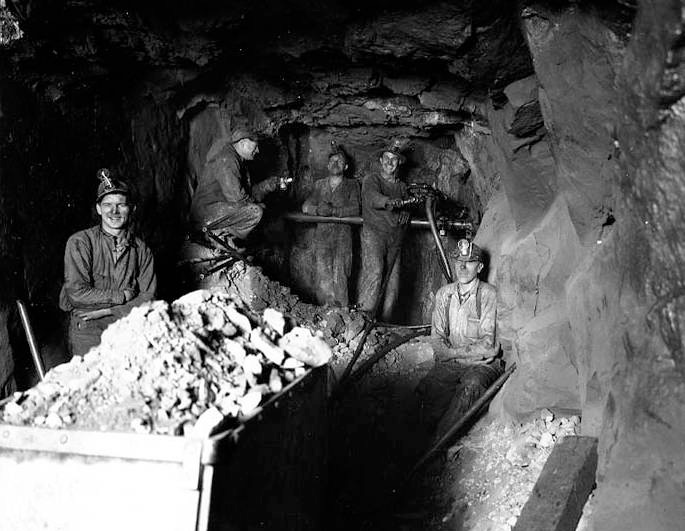

A Northwest Mine

Photo here and in video courtesy University of Washington Archives

photos shown may not be of actual mine

The property of this hidden labyrinth of underground passages was officially located by L.H. and C.H. Gray on January 12, 1897. Unofficially, a year earlier, a couple of men; A.W. McRae and Bud McRae, discovered a ledge of copper ore ¼ mile north of the Great Northern Railroad in Washington State. The property wasn’t named in the archives and one can only guess which it was.

In May of 1897 a mining company was formed to start some exploratory mining on the property, but no real development was commencing.

In February 1900 a contract on the “Jumbo” shaft was completed. The depth of this hole in the ground was 110 feet. With completion, the owners were said to have $300,000 worth of ore inside. Others were skeptical.

During this time, other companies were mentioning claims found in the surrounding areas. Material was being extracted!

Late 1899, a contract set by the Russell Company of Tacoma went ahead in the planning of constructing a smelter for installation at the location. Construction of the 10 ton capacity smelter designed for testing purposes continued into mid June 1900.

Between the times the smelter was being built, the company owning the land was officially reorganized. March 20, 1900 is sometimes quoted as the official starting date for the company, although that date is historically 3 years late.

Many eyes were on this mining facility, particularly the newly constructed smelter by Russels. The outlining mines and miners were watching closely at the success, and practicability of the smelter, so as to take similar steps to secure similar works for their mines. Twenty men worked at the mine now ensuring its success. It was predicted after the aerial tram was completed and ore was regularly extracted from the mine, that it would be one of the first dividend payers in the district.

In June of 1900, the matting plant (to combine the ore together, sometimes with other metals) was completed. During the time the plant was being constructed, the mine was constantly developed. Drifting (creating a near-horizontal passageway in a mine) and raising (A secondary or tertiary inclined opening, vertical or near-vertical opening driven upward form a level to connect with the level above) was performed in the main mine, while ore from the Jumbo was being stoped (creating large underground rooms) then stockpiled waiting transportation to the smelter.

During the spring of 1901, the east side of the property was being developed by the Gray Brothers, and on July 4, 1901 the main mine was sold to the Bunker Hill-Sullivan Mining Company for an undisclosed sum. The new owners stated that they would begin developing the mine as soon as possible using $20,000 worth of new equipment. The east side remained the Gray Brothers property, but only just. The shaft on the east side mine was 30 feet deep with a drift of 17 feet.

Meanwhile the Assistant Actuary of the Metropolitan Life Insurance Company moves out west from New York to oversee the necessary improvements to the property. He later named the area after himself.

October 24th, 1902, the Bunker Hill-Sullivan Mining Company reorganized and added “Copper” to the name. The Bunker Hill and Sullivan Copper Mining Co.’s new president was the New Yorker who just moved out to the area. The property was then capitalized at $1,000,000 with 350,000 shares held as capital stock. Assays (estimates in tests) in 1903 were said to average 8% copper.

With many changes and improvements to the property and owners, 1917 brought the recently renamed Bunker Hill Mining and Smelting Company to actively prospect for capital. The mines on the property were touted as having 6100 feet of tunnels, shafts, raises and stopes, with the fully operational smelting plant and concentrating mill ready to process ore immediately.

In 1917 the war effort increased the copper production, and during this rise in business the Bunker Hill Mining & Smelting Co. sold the mine to the Western Copper Mining Company. The deal was completed on June 6, 1917.

After the war however, the price of copper dropped and the WCMC was left holding the bag. They couldn’t work the mine and make a profit, nor could they sell a devalued mine, so the property sat idle, awaiting a rise in the copper market.

To bring in some capital, the property was scheduled to be logged, but due to an accident, the buildings on site as well as much of the timber were burned.

In an unpublished report to A-C-E Development in 1930, it was claimed that the roads on the property had fallen into disrepair and, upon inspection of the cores form the diamond drilling, found no indication of copper minerals large enough to call ore. The property was still far superior to others, but it would take an investment of over $10,000 to bring the property back into operation.

It is unclear what happened after this report was made, but in the mid 1950’s the property took on new owners once again (Wiatrak Mining), and they paid for the services of various geologists to assess the profitability of the mine. The results weren’t great but weren’t bad either.

In 1973 Mintec Quarries, was contracted to begin the preliminary work on assessing the property. The roads, it was reported, were completely unusable and needed to be replaced, and the tunnels to the mine needed to be mucked out and the shafts drained.

All the work had a large price tag attached to it, and Mintec solicited loans to cover the development costs. After several attempts for financial backing, and repeated rejection, Mintec reverted back to the owners, (Wiatrak Mining), and it has remained the same to this day.

-

-Home